AGENDA - ESD DESIGN & MEASUREMENT: SYSTEMS, SUBSYSTEMS, & EQUIPMENT

In a cold dry environment, like up-north, out in space, or even in Florida where the humidity is 90% outside but only 40% where the equipment is being used, ESD events are possible. Plus, equipment being shipped to Europe and other countries that use the EU EMC requirements must meet ESD limits based upon operational requirements. This presentation covers design and protection of systems and equipment from ESD. An ESD transient doesn't last very long, but it is extreme with a 2-3 Megawatt surge that has high energy to 300 MHz and levels sufficient to cause upset all the way to 1 - 3 GHz. Fortunately some of the most important protection methods are free if they are designed in from the beginning and not added later as a retrofit to a non-functional design.

This presentation covers the five most important design categories for ESD protection: segregation/isolation, PCB/electronics design, cable design, filtering, and shielding.

1. Electron Mobility and Charge Creation

Electron Mobility, Charge Accumulation, and how it occurs

The environment ‘s effect on ESD amplitudes

How ESD couples into systems and destroys semiconductor devices

2. Mechanism of Electro Static Discharge

Triboelectric series

ESD Generated by Floor Materials, Particles, Gases

ESD Damage Levels

Charge Density/Arc Over Distance

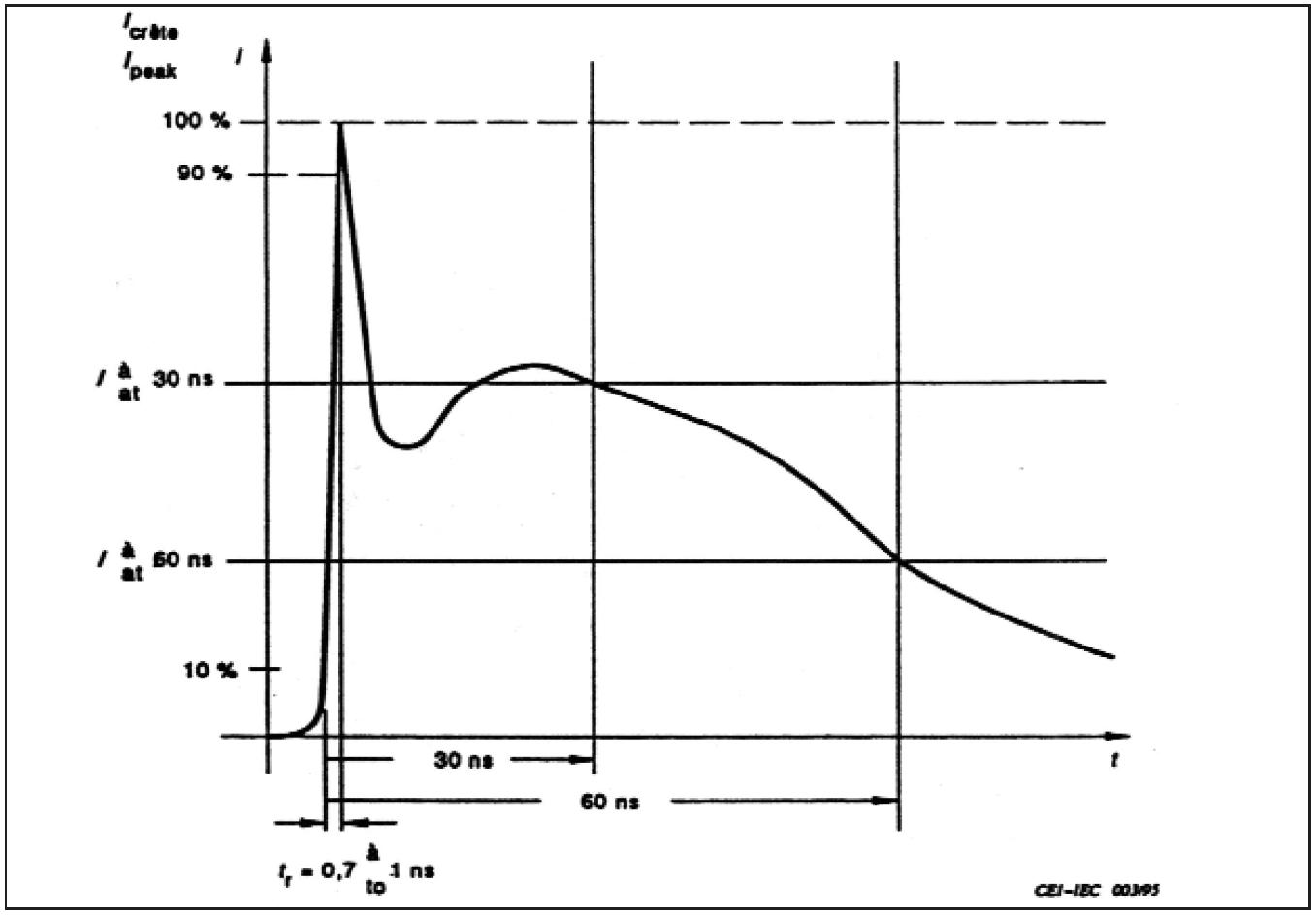

ESD Waveform & Spectrum

Component Failures

3. ESD Coupling into Electronic Systems

ESD Direct and Indirect Discharge Coupling Mechanisms

Radial and Linear ESD Current Flow

Segregation/Isolation

Simplified Loop Pickup Equation

ESD Circuit, I/O & Cable Hardening

4. ESD Circuit, I/O & Cable Hardening

ESD Protection Methods Discussion

ESD protection design of high-speed, logic-based systems

Importance of Multilayer PCB’s

I/O ESD Protection

Differential and Common Mode Radiation Coupling

ESD Control for Interconnect Cables and Connectors

Transient Voltage Suppression Devices

5. Bonding & Grounding

Grounding and Bonding Rationale

Isolating uninsulated grounds

Cable, Connector, Box, and System-Level Grounding

6. Filters & Isolation Transformers

Types of filter designs

Combined Common and Differential–Mode Filter

Filtering Safety Ground

Effect of Parasitic Capacitance and

Poor Mounting on Filter Performance

Typical CM and DM Rejection of Shielded-Isolation Transformers

Combined Shielded-Isolation Transformers and Filters are Not Redundant

7. ESD Shielding

Shielding Effectiveness & Materials

Packaging in Plastic vs Metal

Aperture Attenuation

Aperture Leakage and Its Control

8. ESD Test and Evaluation

Brief Overview IEC 61000-4-2 & IEEE/ANSI ESD Tests

ESD Qualification Test Setup and Testing

Table Top & Floor Standing Equipment

Direct Contact and Air Discharge

Direct Injection Case, Cable, Connector, & Pins

Using ESD as a Diagnostic Procedure

Component ESD Protection

9. Component ESD Protection

Minimum Requirements for an ESD Protected Prototype Construction Area

A significant problem at the workplace

www.ronbrewer