COPYRIGHT (c) 2003 - ALL RIGHTS RESERVED

Ron Brewer

UNDERSTANDING THE EMC DESIGN PROBLEM!

People that have just heard of EMC seem to believe that such problems are rare and no big deal. It's not that way at all. Any electronic system is an EMC problem waiting to happen. Murphy's Law! These problems may occur from within the system (self compatibility/signal integrity), the system may cause another to malfunction, or the system may malfunction because of the surrounding electro-magnetic ambient. These emission or susceptibility problems result from unwanted radiated RF energy or from RF energy conducted on power-control-signal lines.

Everyone has witnessed interference - they see it in action at home and at work. A typical scenario, much like one that the FCC tries to control, might be the interference that occurs on the television when the microwave oven is on or when the kids are doing homework on their microcomputer. RF energy is being radiated from the culprit source and picked up by the TV antenna, by direct penetration into the systems PCB's, and by pickup on the power, control, and signal leads. In addition, RF energy is often conducted along the incoming power-line to the receiver through shared common impedances. In both cases, it is the unwanted RF energy that reaches the receiver that causes it to malfunction. These malfunctions are generally temporary in nature. When the RF source is removed the problem goes away.

Everyone has witnessed interference - they see it in action at home and at work. A typical scenario, much like one that the FCC tries to control, might be the interference that occurs on the television when the microwave oven is on or when the kids are doing homework on their microcomputer. RF energy is being radiated from the culprit source and picked up by the TV antenna, by direct penetration into the systems PCB's, and by pickup on the power, control, and signal leads. In addition, RF energy is often conducted along the incoming power-line to the receiver through shared common impedances. In both cases, it is the unwanted RF energy that reaches the receiver that causes it to malfunction. These malfunctions are generally temporary in nature. When the RF source is removed the problem goes away.

If this is the most exciting part of a program, and someone turns on a microcomputer or other RF source and destroys the TV picture, most viewers are going to be very upset. As a result, the FCC has requirements that state that one cannot design, build, and sell equipment that jams the public broadcast service. The FCC requirements do not address hardening equipment so that it might not be susceptible, they do not address the problems of interference between devices that are not used to receive public broadcast programming, and they do not address health and safety issues. The European requirements go beyond those of the FCC and they do address many of these additional situations.

Interfering conditions may exist that are more than just a nuisance. For example, on board aircraft we find prohibitions against using certain types of electronic devices, especially during the first and last 10 minutes of a flight when the operation of flight control systems are critical. One of the earliest and one of the worst problems is the emissions from FM receivers, because their local oscillator radiation falls in the same frequency range as the instrument landing system (ILS) equipment on the aircraft. Cell phones, remote control toys, and computer systems all rank high on the list of potential RF hazards. As a result, aircraft electronics devices undergo very severe RTCA DO-160 EMC tests. Even then, Federal regulations that prohibit the use of many kinds of electronic devices aboard aircraft are required to assure passenger safety. The military is also concerned about EMI and requires systems to be designed to operate without malfunction in an adverse electromagnetic environment. From a military perspective, it is very important that systems do not create problems in which the mission is lost or in which lives are lost.

The problem keeps getting worse, and has been steadily increasing since the early to mid 1970's when we begin to see a large increase in the use of microprocessor systems. This increase occurred in part because microprocessors were becoming cheaper, mechanical timers could be replaced with microprocessors that were reliable, and because marketing people discovered that the general public was very enamored with microprocessor based systems. During that time the FCC developed the early requirements for computer based systems which were released in docket 20780 and ultimately included in FCC part 15. Today the FCC still controls only systems level radiated emissions and power line conducted emissions in their rules and regulations. The FCC has no susceptibility requirements.

The European EMC requirements that were first released in 1989 ended the era of weak commercial EMC regulations and their associated lack of commercial immunity/susceptibility requirements. It also sent a strong message to many manufacturers that they should have been designing immunity/susceptibility measures into their equipment all along. Many organizations, such as the medical and industrial control manufacturers, had little experience meeting EMC regulations of any kind, and had not previously been required to play the game of EMC regulatory catch-up. These organizations were caught way behind on the learning curve, with few (if any) EMC engineer's available to satisfy the need.

The European Union's (EU) new approach directives are configured so that systems and equipment are classified by function and must meet specific requirements for each classification if product specific requirements exist. Otherwise, depending upon the equipment, the following generic requirements must be met:

- Radiated - almost the same as the FCC requirements

- Conducted - almost the same as the FCC requirements

- Line harmonics

- Line fluctuations

- Electro-Static Discharge (ESD)

- Radiated RF fields

- Electrical Fast Transient (EFT)/Burst

- Surge

- Conducted RF

- Other (Such as magnetic field susceptibility)

EU EMISSIONS REQUIREMENTS

EU IMMUNITY REQUIREMENTS

The EU radiated and conducted emissions requirements are based on CISPR 11 and 22 and are essentially the same as our current FCC requirements. The EU immunity requirements test the susceptibility of the system/equipment to an adverse electromagnetic environment. This represents a major change in commercial EMC requirements. In the USA, only the military has had susceptibility requirements. Now, FDA has placed susceptibility requirements on medical devices such as powered wheel chairs and sleep apnea devices. These new FDA requirements are similar to and in some cases based upon the EU requirements.

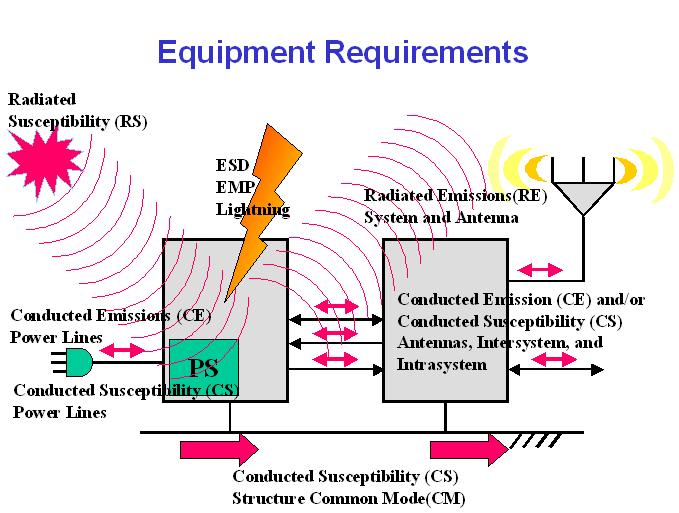

In spite of the multitude of EMC tests that exist to verify compliance to commercial and military EMC requirements, there are basically only four coupling categories: radiated emissions, radiated susceptibility/immunity, conducted emissions, and conducted susceptibility/immunity. When these are compared, designing to meet the susceptibility requirements tends to be more difficult than designing to meet the emission requirements, and designing to meet the radiated requirements tends to be more difficult than designing to meet the conducted requirements.

Bearing this in mind, when designing to meet the EU requirements, there are two distinct problems that must be dealt with: (1) EU conducted immunity, notably the EFT/burst test which is applied to both power lines and control/signal leads at levels up to 4 kV (5ns x 50ns), and (2) EU radiated immunity, notably the ESD test which can be as high as 15 kV (<1 ns) for air discharge. The conducted immunity EFT/Burst test is very severe. The test signal is a very fast transient and has significant energy levels existing at frequencies over 100 MHz. The radiated immunity ESD test is likewise generally more severe than the 1/3/10 V/m radiated RF test. Many EMC test labs are reporting that the majority of the equipment being tested fails to meet thesete susceptibility/immunity requirements.

Thus, if these two problems can be solved, then the remaining requirements will normally be resolved in the process. The immunity hardening is certainly achievable, but it should be implemented early in the design, not after everything else is complete. For example, if the systems/equipment is a low powered digitally based device, it will require approximately 20 to 40 dB more hardening (than required for the FCC emission requirements) to meet the EU conducted immunity requirements, and it will require the same level of EMC hardening (as required for FCC emissions) to meet either the radiated emissions or immunity requirements. However, if the system/equipment combines both low level analog circuits and digital circuits (a common requirement in medical and industrial control equipment), it will still require 20 to 40 dB more hardening for the EU conducted immunity requirements, but in addition, it will now require about 40 dB more hardening to meet the EU radiated immunity requirements.

In new designs, the most cost effective approach to controlling EMC problems requires understanding the synergistic relationship of PCB design, cable hardening, and PCB/enclosure shielding. These and other EMC design practices are discussed in the other articles found on this site.

www.ronbrewer.com